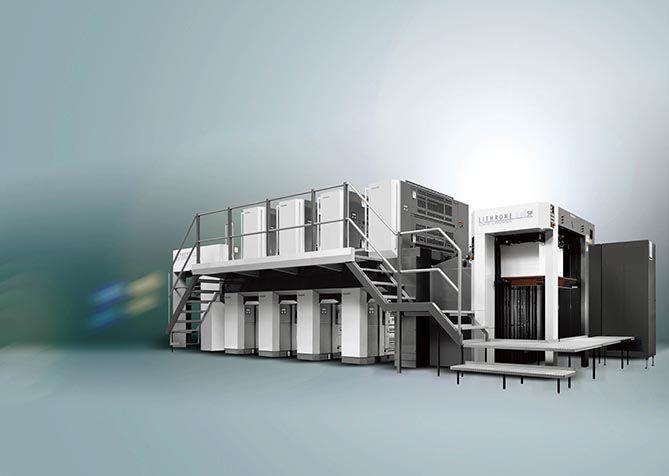

LITHRONE S40SP

Concept

Genesis of a Great Press:

Enhanced Productivity Converges with High Print Quality

The new Komori Lithrone S40SP SuperPerfector combines the exceptional print quality of sheetfed presses with the productivity of web presses. The press was developed by rethinking the remarkable Lithrone 40SP and introducing many of the proven features of the Lithrone S40 series. This endeavor was an extension of Komori's ideal of conceiving all product development from the user's perspective. In addition to featuring a space-saving footprint, the new Lithrone S40SP improves production efficiency and delivers major cost reductions. The press integrates a range of technologies to resolve the issues of front/back print quality differences as well as scuffing and marking.

Features

- Sheetfed quality combined with the productivity of a web press.

- Enormously greater production efficiency due to doublesided one-pass printing and significant cost reductions.

- Printing system that results in virtually no print quality difference between front and back sides.

- Major reductions in paper costs because only one end of the sheet is gripped in double-sided printing. Platemaking approach facilitates operation in cooperation with singlesided presses.

- Basic cylinder array without transfer cylinders between units and delivery-end belt-guide sheet transfer system provide a complete solution to sheet scuffing and marking.

- Two or more times the productivity of a single-sided press on comparable installation area.

| Model | LITHRONE S40SP | |

|---|---|---|

| Number of colors | 1×1 2×2 4×4 5×5 6×6 |

|

| Max. sheet size | mm | 720×1,030 |

| Max. printing area | mm | 710×1,020 |

| Plate size | mm | 800×1,030 |

| Feeder pile height | mm | 1,450 |

| Delivery pile height | mm | 1,450 |

* Performance and numbers may differ from specifications herein. Specifications may also be modified for product improvements.

* Margin for vacuum wheels on back side of sheet required.