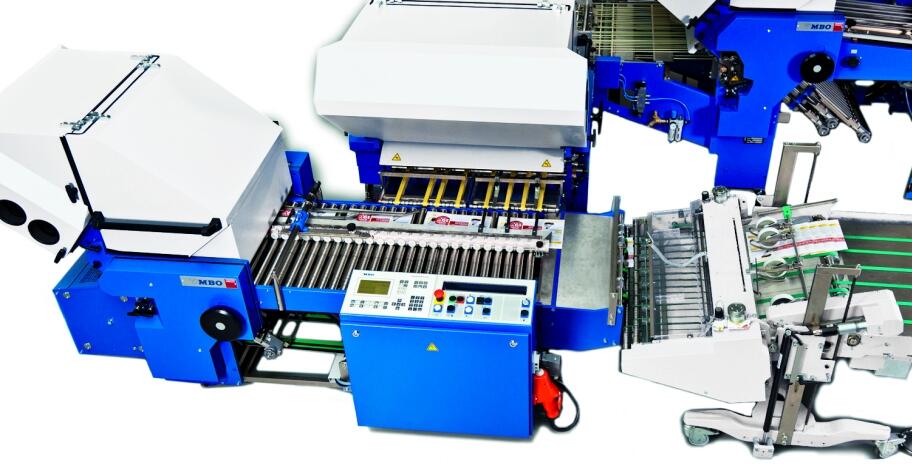

MBO T960

Concept

Folder with high folding precision due to high operating speed and robust construction

Buckle folding machines by MBO convince with their universal application range and unique bandwidth of folding types.

All models of the Perfection series basically stand for the highest possible folding performance and maximum output. MBO folding machines and features are orientated on the users – both regarding practical requirements and the variety of the paper medium. Convenience plays a major role. The simpler the processes and workflows, the more efficient becomes production. With its high performance and excellent quality, the MBO T960 provides the ideal preconditions for highest productivity. A broad range of folding types and individual automation options up to full automation guarantee that the Perfection series lives up to its name.

The equipment features of our folding machines have been especially designed for the purpose of their application. We never rest on our well-proven product development achievements but always try to recognise new requirements as early as possible. Ideally soon enough to offer you a solution before you even face the problem. Some of these special solutions can be found on the MBO T960.

A special conveyor table that can be used on folding unit I opens up new production options for you with a single additional investment. The conveyor table permanently affixed to folding unit I is equipped with what is known as an alternating deflector. The alternating deflector can distribute the sheet stream from folding unit I alternately on two sidelays in folding unit II. This halves the mechanical speed of the second folding unit and this unit is able to process the higher output of the first folding unit, particularly with landscape formats. Halving the speed guarantees high folding quality and reliable corner deflection in folding unit II. This means that for many products that could often produce a higher speed in the first folding unit, but that are slowed down by the second folding unit (fold variations, difficult corner deflection, flying corners with thin products), the output can be increased by up to 40 %. All with just one turn of the handle.

In addition to the increased output, there is another effect that plays a significant role. Overrunning images are no longer controlled via multiple crossfolds. Instead, the quality is set in the first folding unit itself via the first fold.

A high net output can be achieved thanks to the waste sheet deflector integrated into the conveyor table. Incorrectly folded sheets and double sheets are detected by the ultrasonic double sheet control here and ejected during production before the alternating deflector.

Features

- Excellent folding quality even for very high outputs

- Double stream production for higher output

- Full automation option and option to automate individual functional groups

- Maximum variety of folding types for flexible application

- Highest operator convenience thanks to unique MBO features

| model |

MBO T960 |

|

|---|---|---|

| Max. sheet size | mm |

Palletized feeder:960x1,450 |

| Min. sheet size | mm |

Palletized feeder:250x300 |

| Sheet thickness (weight) | gms | 35~250 |

| Speed | m/min | 230 |

|

Number of buckles |

plates | 4 or 6 |

| Available configurations |

Second unit for parallel folding(4 or 6 plates) Third unit for parallel folding(2 or 4 plates) |

* Performance and numbers may differ from specifications herein, and specifications may also be modified for product improvements.